Better Bites: FoodPlant's Protein-Packed Puff Snack is a Guilt-free Treat

FoodPlant, a subsidiary of SIT, has created a high-protein, plant-based puff snack that proves healthy eating does not mean sacrificing taste and crunch.

Snacking on chips and crackers laden with fat and salt is often a guilty pleasure.

Enter S-Pop, a new plant-based puff snack that offers a guilt-free crunch. Developed by FoodPlant, this innovative snack is low in fat, with no added oil, and contains significantly less sodium than the typical bag of chips and crackers on supermarket shelves-. Made with mung bean protein isolate, rice flour, and corn grits, the snack boasts an impressive protein content of over 50 per cent by weight.

The healthy snack was created to showcase FoodPlant’s capabilities in food innovation and advanced manufacturing. Launched in 2022 as a subsidiary of the Singapore Institute of Technology (SIT), FoodPlant partners with food manufacturers to co-create healthier, commercially viable food products.

S-Pop is a high-protein, low-sodium plant-based puff snack—available in curry and seaweed flavours—developed by FoodPlant using advanced extrusion technology. (SIT Photo: FoodPlant)

From Concept to Crispy Bite

S-Pop began as a deliberate initiative to demonstrate how food technology can make healthy eating exciting and sustainable. The snack was developed using extrusion technology — a thermo-mechanical process that applies pressure and shear to cook and expand simple ingredients, creating light and crispy textures commonly found in puffed snacks.

Designed under the direction of Associate Professor Lim Bee Gim, founding CEO and Technical Advisor of FoodPlant, this innovation also reflects her ongoing work in advancing sustainable protein solutions through the national Proteins4Singapore (P4SG) programme.

“The easy route would have been to create a typical indulgent snack, one that is high in fat, salt, and refined carbohydrates,” she shared.

“But I felt strongly that if we were to create something, it had to be meaningful — a product that reflects where sustainable food innovation should be heading: high-protein, nutritious, and future-ready.”

This vision guided the team to develop a puff that balances taste, texture, and nutrition. It appealed to younger consumers seeking better options, as well as to seniors who need more protein for muscle health. The project also demonstrated how FoodPlant’s process expertise and P4SG’s research insights can work together to drive responsible, sustainable food innovation in Singapore.

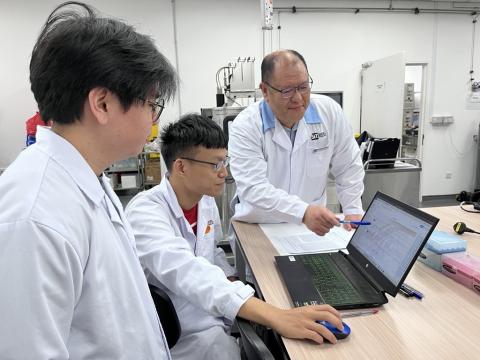

A/Prof Lim Bee Gim (right), with FoodPlant Project Manager Yan Li Hui (centre), and Quality Assurance Executive Angeline Goh (left) examining puffed snacks produced using the twin-screw extruder. (SIT Photo: FoodPlant)

Engineering the Perfect Protein Puff

Behind S-Pop’s unassuming appearance lies a highly scientific process. A dry mix of ingredients and water is combined to form a dough, which is then fed into a twin-screw extruder. Inside, a precise combination of heat, moisture, and shear cooks the mixture, building pressure until it is forced through a die plate.

As the dough exits a 3 millimetre die, the sudden pressure drop causes it to expand about 1 centimetre in diameter.

Achieving this with such a high-protein content, however, was no easy task. “The more protein you add, the harder it is to achieve a good puff,” A/Prof Lim explained.

To address this challenge, the team carefully optimised key extrusion variables — feed moisture, barrel temperature, screw speed, throughput, and screw configuration — while monitoring melt pressure and temperature throughout the run. Through systematic trials, they established a precise processing window that produced a crisp puff without compromising on nutrition.

FoodPlant’s pilot-scale system made rapid iteration and fine-tuning possible. This flexibility is one of FoodPlant’s key strengths — enabling low-risk experimentation and co-development with partners.

With the formulation perfected, the next step was to share it with the world — not just through research papers, but through real experiences that connect innovation with people.

The Proof is in the Tasting

With a successful prototype in hand, a taste test was next. S-Pop was first introduced in October 2025 at SIT Sustainability Day. It has since been served at FoodPlant’s training courses and visits by local and overseas guests, giving participants a literal, firsthand taste of how technology and nutrition come together.

A/Prof Lim recalled serving the snack to two visitors from Japan, who "kept eating and eating”. This sensory evaluation, she noted, is vital.

“Tasting makes the abstract ideas of sustainability and health tangible. We want people to see that a healthier snack can deliver flavour and crunch.”

S-Pop Shines at TFoodS 2025

S-Pop subsequently made a public debut and took centre stage at TFoodS 2025: Introducing Alternative Proteins, a public exhibition organised by P4SG. Held on 9 November 2025, the event showcased the latest innovations in sustainable food production and alternative proteins.

Associate Professor Lim Bee Gim engaging the public at TFoodS 2025, gathering feedback on the taste of S-Pop as a healthier snack. (SIT Photo: FoodPlant)

Associate Professor Lim Bee Gim (third from left) with the scientific advisory committee for Proteins4Singapore (P4SG) programme. (SIT Photo: FoodPlant)

Senior Minister of State Mr. Zaqy Mohamad, the Guest-of-Honor, who also took the opportunity to try S-Pop for himself at SIT’s booth at TFoodS 2025. (SIT Photo: FoodPlant)

The event provided a perfect platform for FoodPlant to introduce S-Pop to a wider audience, including industry professionals, researchers, and food innovators. Attendees experienced firsthand how this healthy, protein-packed snack balanced taste, texture, and nutrition in a convenient and sustainable form. The response was overwhelmingly positive, with many visitors returning for seconds—proof that science and innovation can deliver tasty snacks.

Associate Professor Lim Bee Gim (3rd from left) in a panel discussion at TFoodS 2025 providing exper insights on the topic of alternative proteins. (SIT Photo: FoodPlant)

During the event, A/Prof Lim also participated in a panel discussion on next-generation alternative proteins where she emphasised the importance of trust in new food technologies. "Trust that innovation will not compromise safety or quality, and trust that new ingredients and technologies can seamlessly integrate into existing systems," she explained.

Co-creating Commercial Crisps

More than just a healthy snack, S-Pop reflects FoodPlant’s role as a capability hub for Singapore's food industry, supporting companies in exploring and scaling sustainable food products.

“We want to give companies the confidence to scale and turn upstream research and development into consumer-ready products,” A/Prof Lim added.

She envisions companies partnering with FoodPlant to commercialise S-Pop or developing their own versions. “We want to inspire more companies to launch nutrient-dense, plant-forward products that support the HealthierSG movement, and get more people looking into sustainable food choices,” she added.

As consumer needs evolve and demand for high-protein, nutritious foods grows, FoodPlant remains committed to translating research into commercially viable products that support healthier living. This collaborative model, she noted, can help build local capabilities and strengthen Singapore’s ecosystem for healthier food manufacturing.

![[FA] SIT One SITizen Alumni Initiative_Web banner_1244px x 688px.jpg](/openhouse2025/openhouse/centre-professional-communication/openhouse/directory/sites/default/files/2024-12/%5BFA%5D%20%20SIT%20One%20SITizen%20Alumni%20Initiative_Web%20banner_1244px%20x%20688px.jpg)