![[FA] SIT One SITizen Alumni Initiative_Web banner_1244px x 688px.jpg](/openhouse2025/sit-teaching-and-learning-academy/directory/centre-professional-communication/openhouse/sit-teaching-and-learning-academy/directory/sites/default/files/2024-12/%5BFA%5D%20%20SIT%20One%20SITizen%20Alumni%20Initiative_Web%20banner_1244px%20x%20688px.jpg)

NAMIC Hub@SIT

Overview

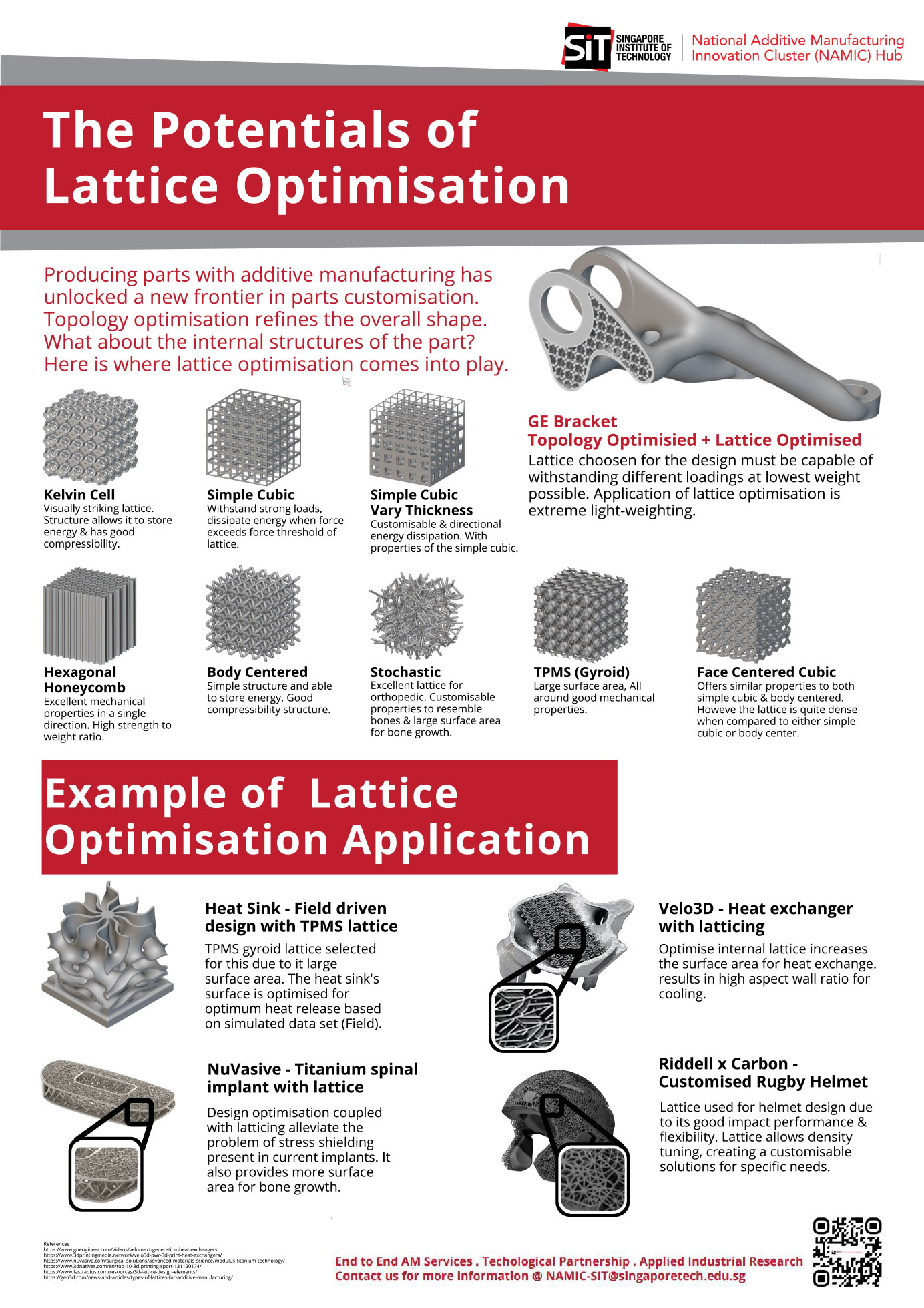

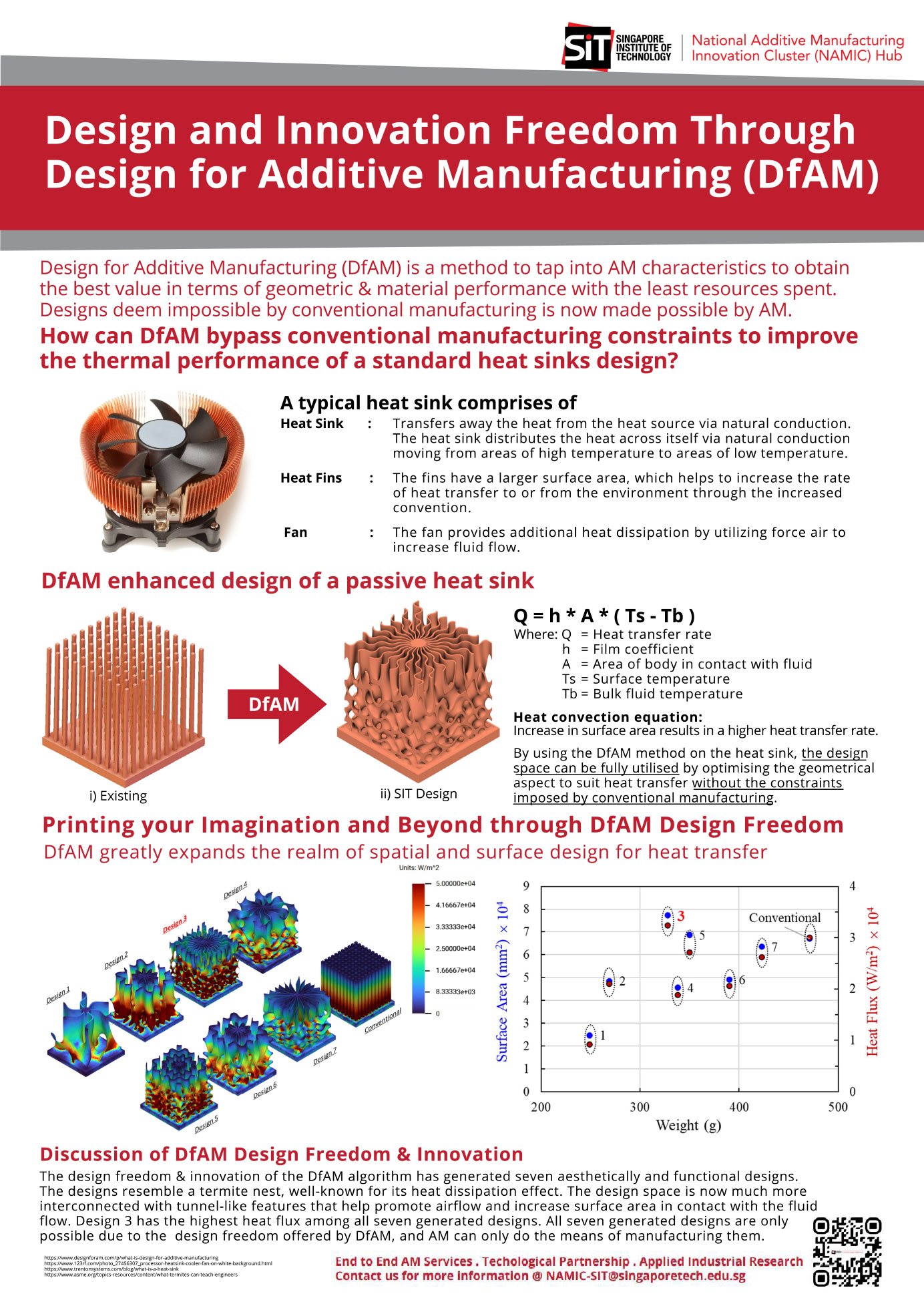

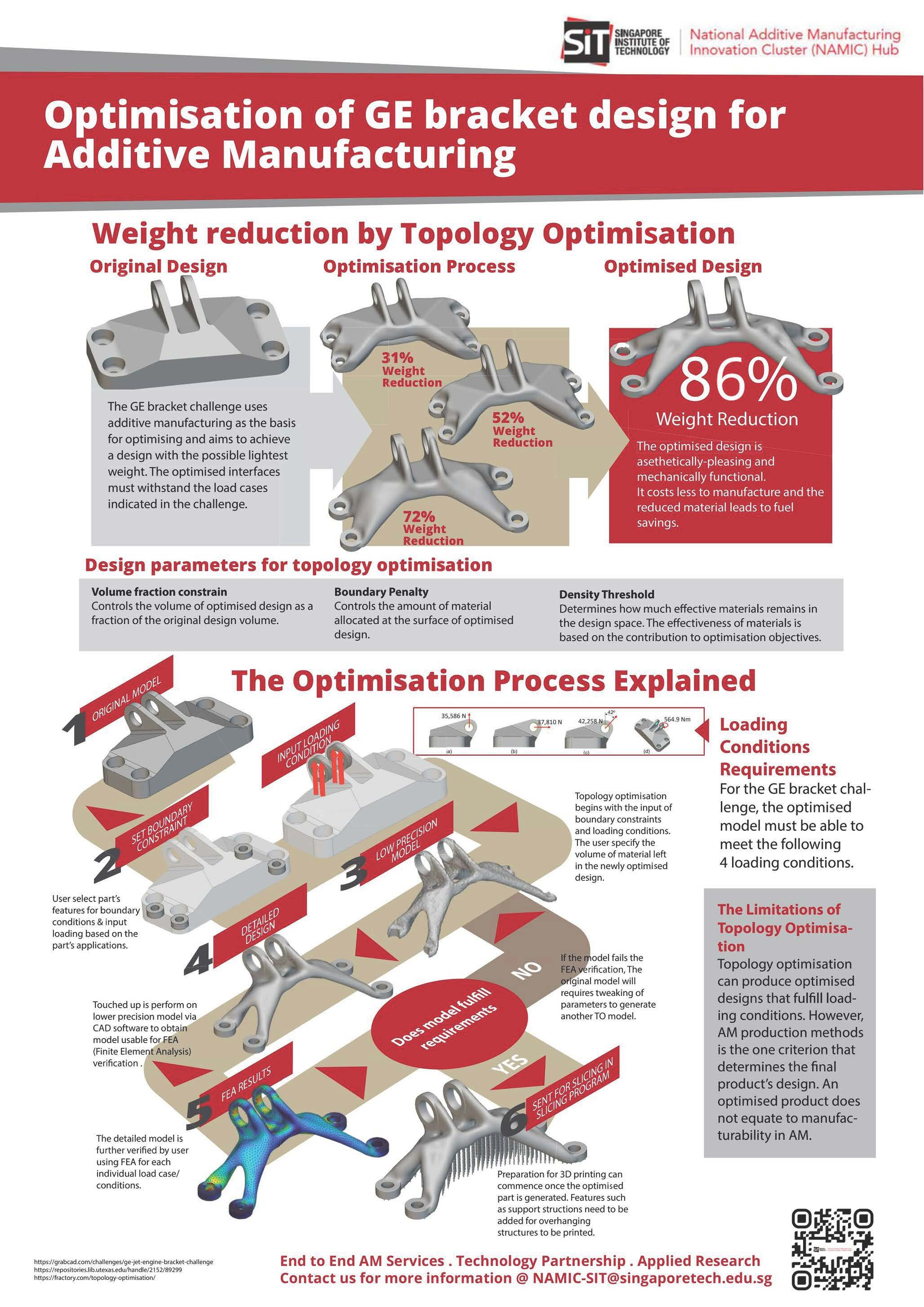

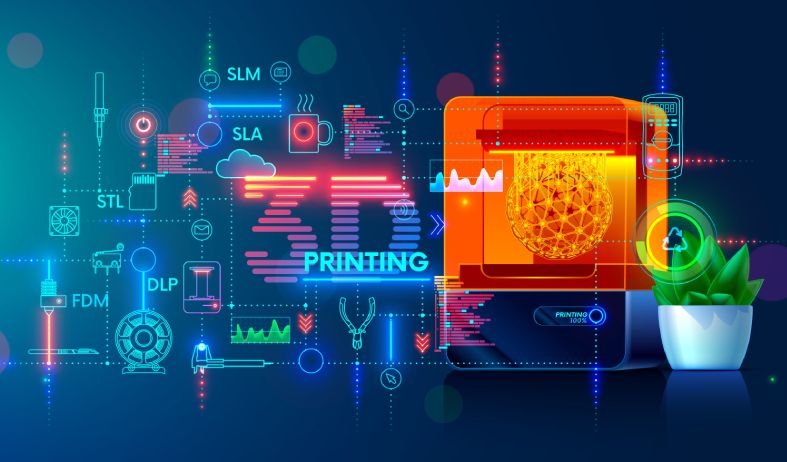

The National Additive Manufacturing Innovation Cluster (NAMIC) Hub@SIT is at the forefront of developing advanced Additive Manufacturing (AM) technologies that catalyses industry transformation. We aim to unlock the full potential of AM through co-development of innovative solutions, with a particular focus on Design for Additive Manufacturing (DfAM) capabilities and emerging technologies.

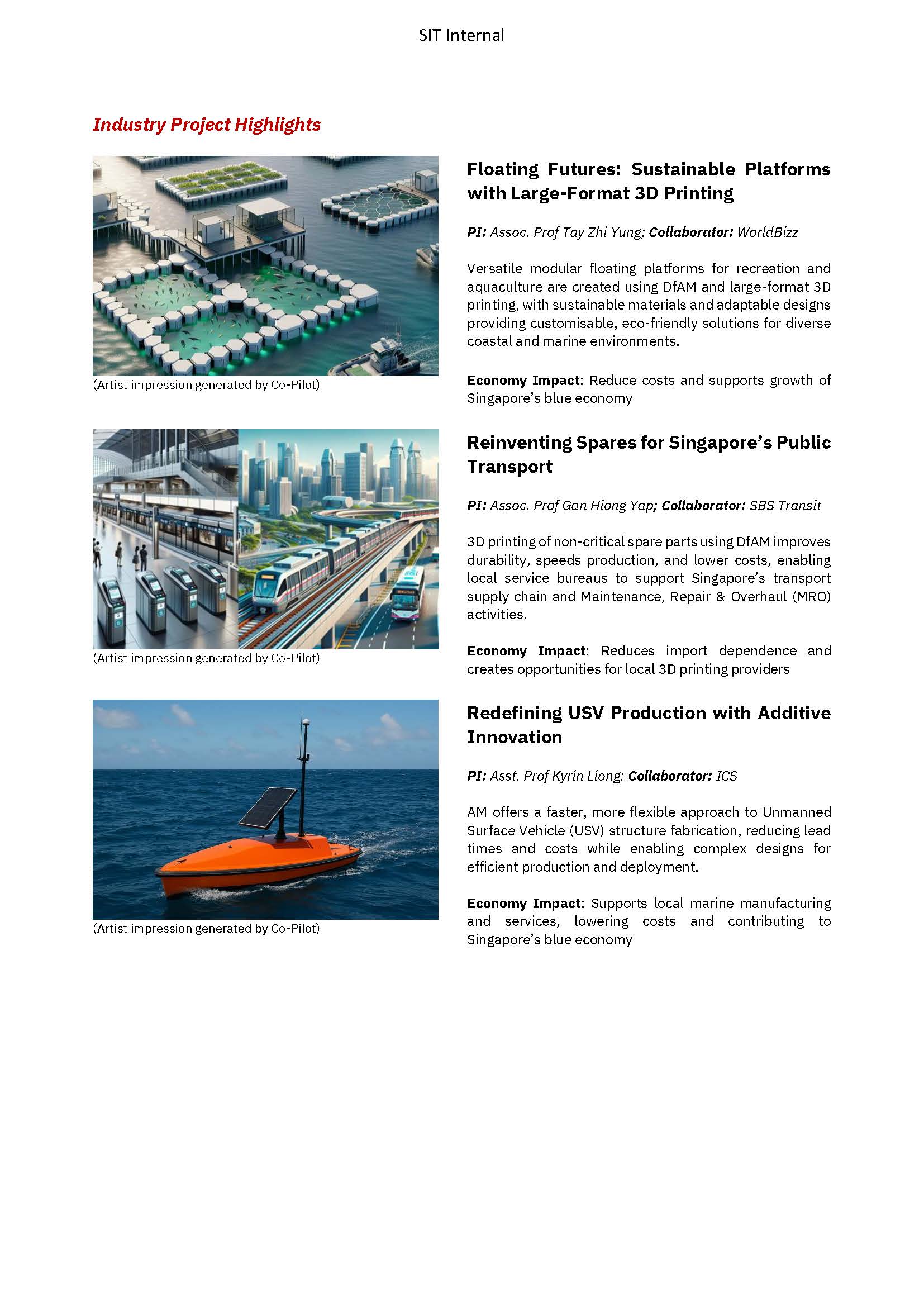

One of the key areas we are exploring is the development of more efficient and compact heat exchangers for modern equipment. Through collaborations with leading corporations, we are tapping into the power of computational shape optimisation technologies driven by fluid and thermal simulation data. This has led to the development of high-performance heat exchanger designs that were previously impossible to achieve with traditional manufacturing methods.

For more information on the NAMIC ecosystem, click here.

Vision & Mission

VISION

To be the catalyst of transformation to boost participating companies’ competitive strengths through additive manufacturing technology.

MISSION

- To be a focal resource center for targeted niche industries, acquire relevant knowledge, and provide manpower training to build AM capabilities in participating companies.

- To support the industry to innovate with speed and efficiency while improving how things are currently being manufactured, maintained, and replaced.

- To be an AM-orchestrator by connecting different partners and facilitating interactions that could identify new or nascent AM opportunities.

Our Areas of Focus

Land Transport

Powering rail and road maintenance and operations to excellence.

Marine & Offshore

Supporting the Marine and Offshore industry with speed and efficiency.

Defence and Space

Accelerating Innovation for Security and Exploration.

Sustainability AM

Shaping a sustainable future for AM.

Our Capabilities

- Reverse Engineering / 3D Optical Scanning

- Design for Additive Manufacturing

- AM Machines Ranging from Polymer to Metal

- Precision Machining

Our extended capabilities includes:

- Filament & Metal Development and Characterization

- NDT Laboratory Accredited by NDTSS for I, II, III*

- Precision Hybrid LPBF (Metal)

- Large Format Pellet Extrusion Printing (Thermoplastic/composite)

- Production Metal Printing

- Scalable Metal AM

Our Services

![]()

Design for Additive Manufacturing

NAMIC Hub@SIT offers expert design consultancy services that ensure the functionality and printability of your existing and conceptualised parts. Utilising advanced simulation software and DfAM principles, we work to optimise part performance while minimising the waste and resources typically associated with design iterations and prototyping.

Development and Characterisation of Materials

At NAMIC Hub@SIT, we specialise in the development and refinement of materials that cater to the unique needs and requirements of our clients. Whether it's developing new formulas from scratch or customising existing recipes, we're committed to delivering materials that meet your exact specifications.

![]()

Technology Development

Collaborate with NAMIC Hub@SIT to co-develop new technologies that will advance your company's technological capabilities in AM. Our subject matter experts will work closely with your team to bring your vision to life, leveraging their extensive knowledge and expertise in the field. With our co-development approach, you can expect to achieve breakthroughs in technology and take your company's capabilities to the next level. Areas of collaboration include:

- Finding new adoptions for the developed technology

- Technology refinements

- Technology consultancy

![]()

Professional Development

We believe that continuous learning and knowledge sharing are critical for staying ahead in the industry and driving innovation forward. NAMIC Hub@SIT is committed to providing professional development opportunities to industry professionals through various initiatives:

- Modular CET courses that can be tailored towards postgraduate qualifications or specialist certificates, providing industry-relevant training that can be stacked to suit individual career goals.

- Guidance and knowledge sharing during collaboration projects, empowering companies to develop new products and capabilities using additive manufacturing technology.

- Industrial sharing sessions hosted by NAMIC Hub@SIT, where practitioners from different organisations can discuss and exchange best practices and innovative solutions to common industry challenges.

![]()

Minimal Viable Product Development

Unlock the full potential of your ideas with NAMIC Hub@SIT's state-of-the-art 3D printing capabilities. Our extensive range of printers enables us to carefully select the most suitable printing methods for your project, expediting the design iteration process and scaling production accordingly. With this level of flexibility, we can help you create functional prototypes quickly and refine them over multiple design iterations, bringing you closer to a near-finished product in a fraction of the time.

Our Team

Our Faculty

Our faculty members are experts who possess the specialised knowledge and skill sets necessary to effectively facilitate industry projects. By partnering with our team, industry collaborators can benefit from the expertise of our faculty members and the exceptional results they deliver.

-

Marine Offshore Digitalisation

-

Design for Additive Manufacturing

-

Additive Manufacturing Technology Development

-

Food Printing

-

Additive Manufacturing Standards (Tribology, Wear & Tear Analysis)

-

Advanced Manufacturing

-

Additive Manufacturing Material Science

Grants

Discover the extensive range of grant schemes available to industry collaborators through NAMIC Hub@SIT. These three distinct grant programmes cater to projects at various stages, from proof-of-concept and validation to industry adoption, ensuring that all project needs are met. Take advantage of these grants today to accelerate your industry collaboration with us.

NAMIC - Rapid Concept Funding (RCF)

Grant Funding

- Up to $28k

- Funding to research performer

- 1:1 co-funding* from collaborator

Grant Support

- Fast validation of concept, design, or process using AM

- Part identification, DFAM & fabrication

- Gateway to Full Project Funding (FPF)

Project Duration

6 - 12 months

NAMIC - Full Project Funding (FPF)

Grant Funding

- Up to $280k

- Funding to research performer

- 1:1 co-funding* from collaborator

Grant Support

- Ready-for-market efforts

- Technology development & validation

- IP development and/or licensing

- High business viability

Project Duration

1 - 2 years

Enterprise Singapore - Enterprise Development Grant

Grant Funding

- Grant cap on case-by-case basis

- Funding to SME company

- Min 30% co-funding from SME

Grant Support

- Proof of Value

- Scale-up and Go-to-market efforts

- Technology deployment

- IP development and/or licensing

Project Duration

1 year

Our Projects

Past Events

Engineering and Tech Programme Scholarship (ETPS) Workshop 2025

Industry Seminar: Uncovering Opportunities in Large Format AM

IES Railway & Transport Chartered Engineers Night 2025

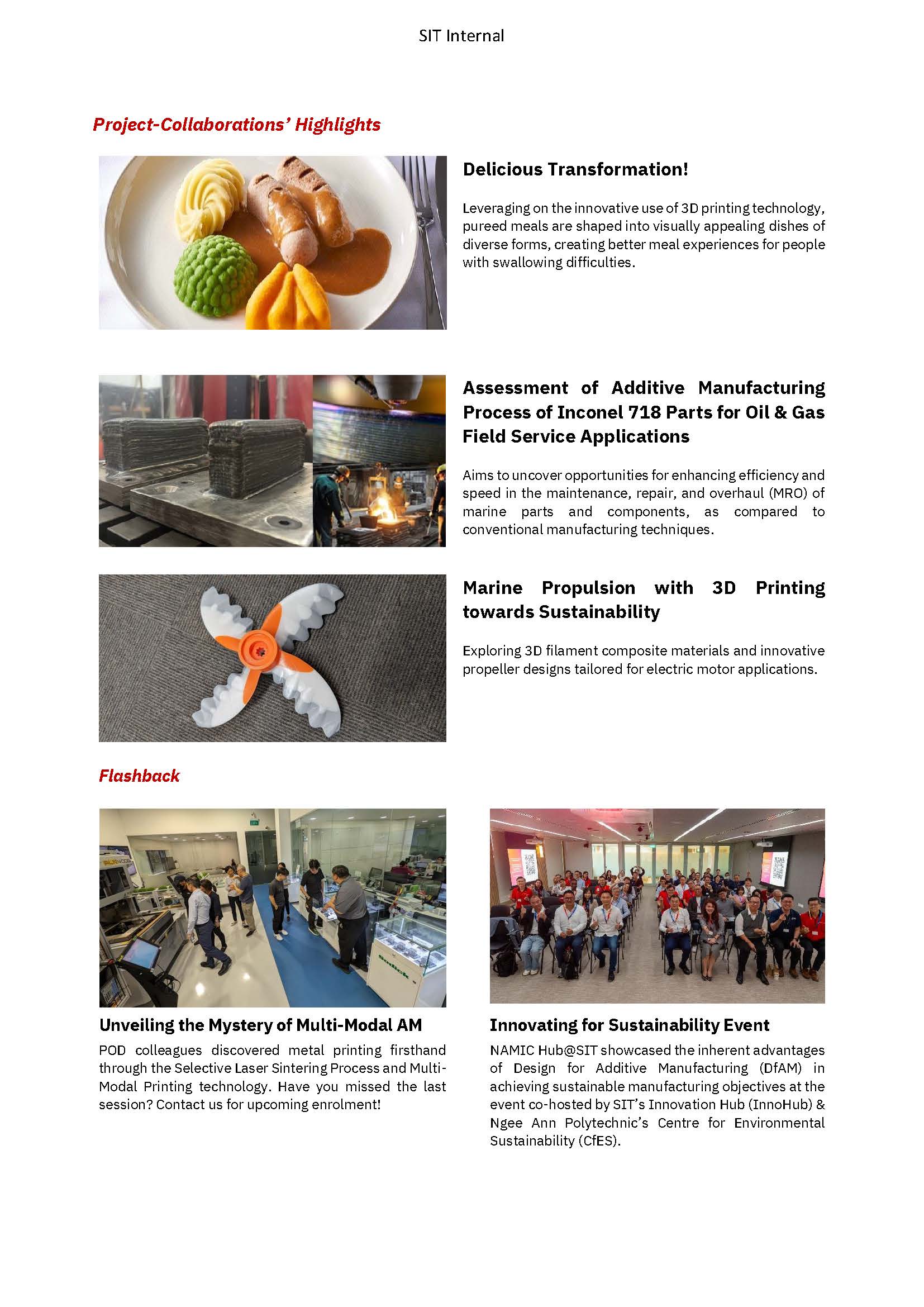

NAMIC Hub@SIT shared an additive manufacturing (AM) application in the rail sector and a broader showcase of AM use cases, highlighting the potential to unlock AM opportunities across the railway and transportation industries.

ASME Student Section Industrial Visits to Additive Innovation Centre At A*STAR

NAMIC Hub@SIT shared on AM application in both engineering and non-engineering industries.

Scarce City" an Art x Tech Exhibition, An immersive 3D Printed Environment

SSTC-SIT: Unlocking New Possibilities with Additive Manufacturing and Metal 3D Printing

NAMIC Hub@SIT has shared the areas of AM in Industry 4.0 and how products using Design for Additive Manufacturing will contribute to a more sustainable future.

AM Workshop in collaboration with Engineering Design & Solutioning Micro-credential

SIT Urban Railway Technology (URT-CET) 3D Printing 2024 Learning Trip to Local AM Service Bureau, ELH

IEEE-SIT Student Chapter 3D Printing Workshop 2024

MSPACO 3D Printing Challenge (Sustainability Interior Design)

Unveiling the Mystery of Hybrid AM

Innovating for Sustainability Event

Project Inspire (SIT-VJC Bootcamp 2024)

SIT-SSTC MNO AM Learning Journey 2023

Industrial Transformation Asia Pacific (ITAP) 2023

SIT-SSTC MOU Signing Ceremony 2023

Art Tech Pecha Kucha 2023

SIT-ESG 2023 (Enterprise Singapore)

SIT-SNEF 2022

Singapore Week of Innovation & Technology (SWITCH) - 2022

SIT Urban Railway Technology (URT-CET) 3D Printing Learning Trip 2022

Contact Us

To learn more about the services we offer or the grants available, please fill out the form below. We will respond to your inquiry as soon as possible.

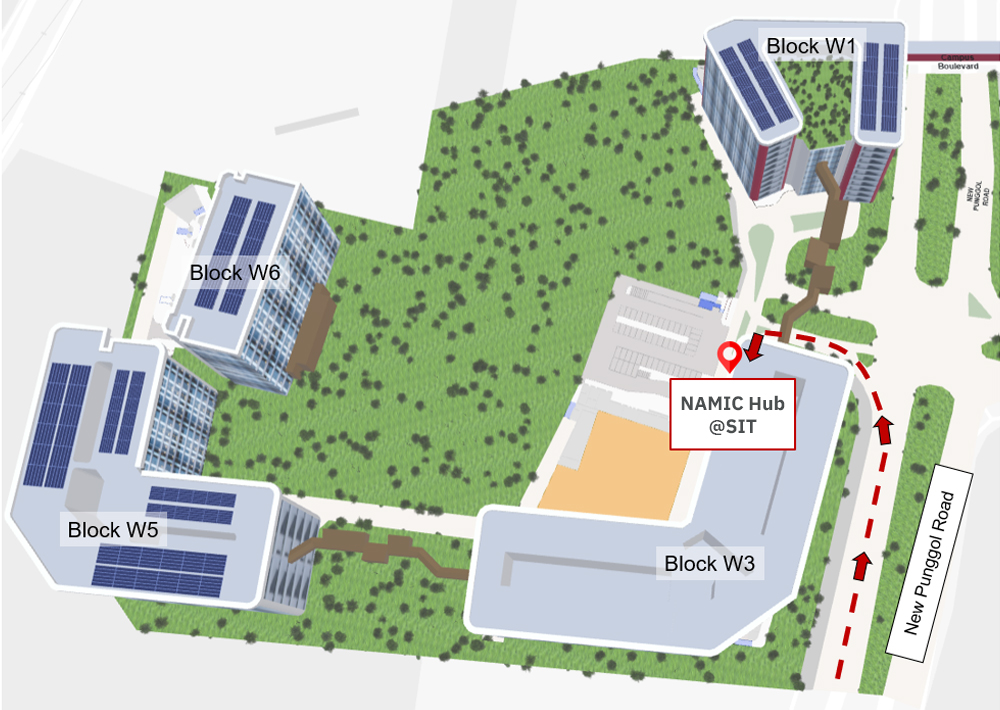

We are located at:

Singapore Institute of Technology

W3-01-105

1 Punggol Coast Road

Singapore 828608