SIT’s Master of Engineering programme gave Mavis Leong the chance to research solutions to address real problems she faced in her day job.

The Hong Kah North Community Centre (CC) is always bustling with people on weekends. But a large contraption placed along the corridor has drawn even more visitors (and some curious stares). Made of two metal doors supported by beam structures, it is surrounded by a crowd of seniors waiting for their turn to walk through. Volunteers stationed nearby then gather their feedback: Which door did they feel was easier to open, and did the process feel smooth for them?

This peculiar sight is part of user testing for a research project by Industrial Master’s student Mavis Leong, who wanted to improve the design of mechanical door closers by making them easier to open, especially for those who are less mobile.

The idea may sound niche, but Mavis is no stranger to the subject. In her day job as a staff research and development engineer at access solutions company dormakaba, she pays particular attention to the door closer – a mechanical device that shuts a door automatically in a controlled manner. Over the years, the 34-year-old discovered that users with limited strength or mobility, particularly seniors, often struggled to open such doors.

Mavis turned an industry challenge into an innovative research project — exemplifying SIT’s blend of academic rigour and real-world impact through its Industrial Master’s programme. (SIT Photo: Keng Photography)

When Mavis enrolled in the Singapore Institute of Technology (SIT)’s Master of Engineering programme in 2023, it gave her the opportunity to research a solution to improve the usability of door closers. The programme allowed her to deepen her specialist knowledge and pursue a postgraduate education without leaving her career — something made possible through SIT’s unique Industrial Doctorate and Industrial Master’s (ID/IM) programmes.

Designed for working professionals, the ID/IM programmes enable students to tackle real-world engineering challenges identified through their employers or industry partners, while being supported by SIT faculty mentors who guide them in applying rigorous research methods and developing practical solutions. This close collaboration ensures that research outcomes deliver meaningful impact to both industry and society.

Mavis’ research project involved user testing, with several seniors taking part. (Photo: Mavis Leong)

Price vs Functionality

Typically installed on the door frame, a door closer combines spring force with hydraulic pressure to regulate how a door closes. When a door is opened, the spring is compressed. On release, the spring will push the door back to a closed position, while the hydraulic system ensures this is done gently without slamming. Door closers ensure security and convenience, but also make doors feel heavier to open.

At her company, Mavis realised that a door closer’s performance is closely tied to its price point. Premium models which can cost up to thousands of dollars had automatic mechanisms that were easier to use, delivering a smooth user experience. But cheaper mechanical options that retailed under $100 required much more strength to manoeuvre. “There are (door closers) of a lower price point. But in terms of functionality, they are not that great,” she said.

She wanted to create an add-on, cost-effective solution that would improve the performance of the existing door closers. Her idea: a guide rail filled with compressed gas that would reduce the effort required to open a door.

“If you have a container of gas with a certain pressure and an area whereby it acts on, that becomes your force. It’s this assisting force that’s acting on the door during opening,” she explained.

Attached to the door closer, the guide rail would act as an additional source of force. The effect would be like having an additional person helping one push the door open, making the door feel lighter, she added.

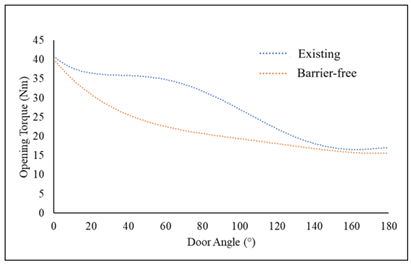

Graph compares the effort required to open doors with existing door closers, versus the ideal barrier-free version. (Photo: Mavis Leong)

Consider a graph with force used as the Y-axis and the door angle as the X-axis. “Ideally, you want the force (used) to keep dropping as you open the door, so the graph is shaped like a playground slide,” she explained.

Putting Theory to the Test

Initially, Mavis had planned to complete her research project with a working theory and prototype of the guide rail. But her industrial supervisor suggested user testing to understand user behaviours. “Having real user input would make my whole project even more complete,” she said.

New to user testing, she found the process challenging. First, she needed participants. Thankfully, she was able to tap on a pool of about 60 seniors from the Hong Kah North Community Club, where she volunteers at.

Second, she needed volunteers to help her during the study. Her academic supervisor, Associate Professor Alfred Tan, suggested she turn to the SIT-run platform, ReadyTalent, to recruit student assistants. These student volunteers assisted with registration and were on the ground to help participants throughout the study. Through this collaboration between academia, industry, and community, Mavis experienced what SIT’s applied research philosophy stands for — solving real problems for real people.

Mavis focused on building the doors for the user testing – one with a regular door closer, and another with her attachment on it. During the study, she observed participants’ body language. When users struggled to open the door, they often relied on different body parts or both hands to prop the door open. Some participants would even wriggle through the gap in the door as it closed. To better understand their experience, Mavis also did short interviews with participants after the trials.

On paper, her calculations were flawless. But the results from her user testing proved otherwise. About 30 per cent of the users said they felt no difference between the two doors.

That was when she realised that while her theory was sound, her prototype needed more rounds of fine-tuning before it could be brought to market. The experience taught her the importance of bridging the gap between theoretical calculations and real-world outcomes. “It made me realise that engineering isn’t just about function or compliance – it’s about people,” she said.

Mavis visited dormakaba’s Switzerland office to participate in dormakaba’s Open Hackathon, which took place from 14 to 18 September. (Photo: Mavis Leong)

Mavis and her team presented their idea at dormakaba’s Open Hackathon this year, an annual innovation sprint where 19 teams transformed bold ideas into working prototypes. Their winning solution stood out for its real-world impact and potential to enhance customer experience.

The project has since been acknowledged for its direct application in guiding dormakaba’s barrier-free product development and advancing inclusive design in the built environment. Currently in its proof-of-concept stage, the invention is undergoing further iterations before Mavis and dormakaba consider patenting or deployment.

Graduating from the Industrial Master’s programme this year, Mavis aims to leverage her experience to contribute to more user-focused and accessibility projects for underserved communities.

“Ultimately, I hope to influence industry standards, contribute to more inclusive product strategies, and mentor future engineers to design with empathy, not just efficiency.”

![[FA] SIT One SITizen Alumni Initiative_Web banner_1244px x 688px.jpg](/sites/default/files/2024-12/%5BFA%5D%20%20SIT%20One%20SITizen%20Alumni%20Initiative_Web%20banner_1244px%20x%20688px.jpg)