One focused on the tiny and reaped great benefits. Another spent time to save lives and livelihoods. The last zoomed in on efficiency. Together, these students target common issues faced by marine companies to make a difference.

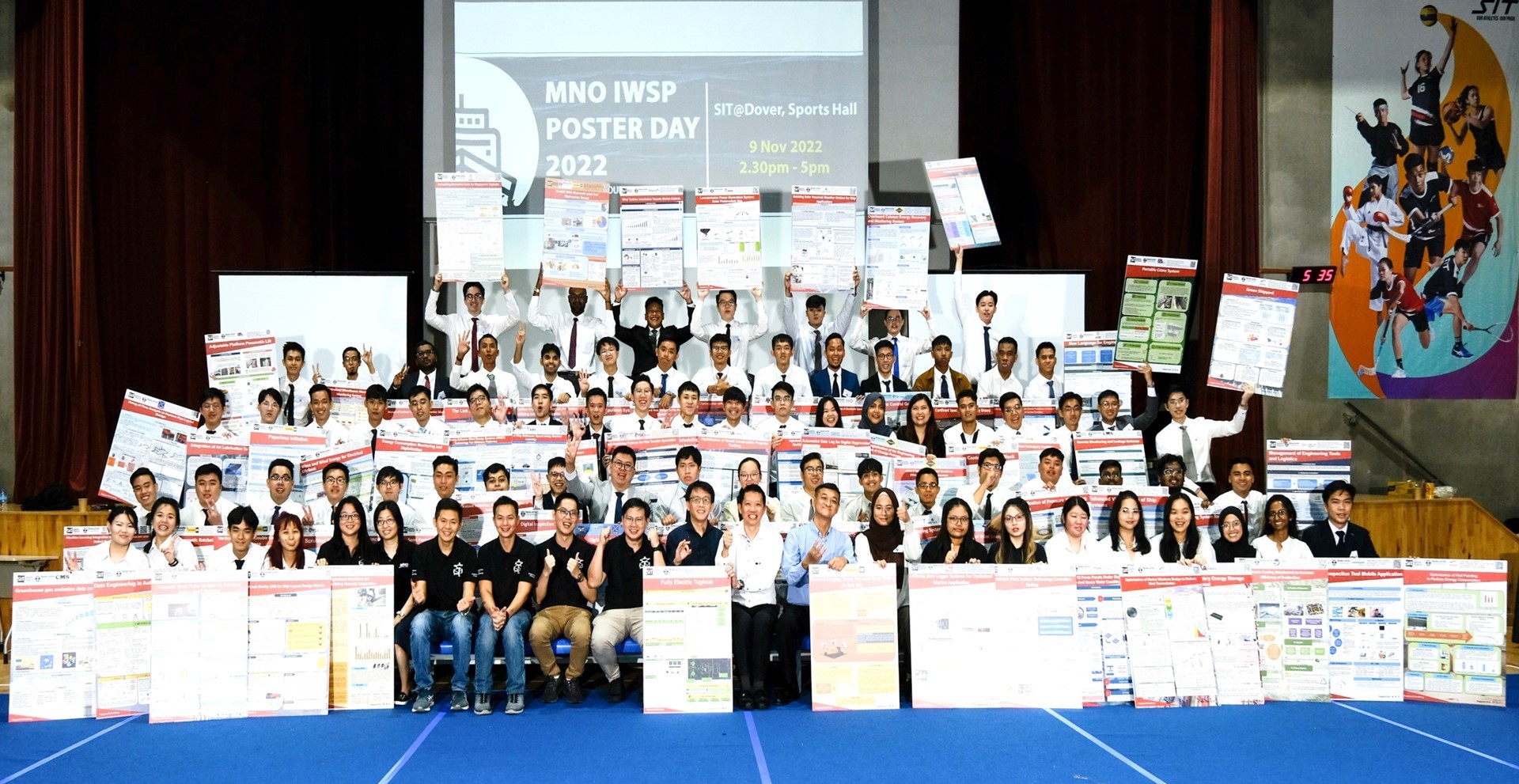

Third-year students with their posters, and professors from the Marine Engineering, Naval Architecture and Offshore Engineering degree programmes at the Marine Programmes IWSP Poster Day 2022. (SIT photo: Thomas Lim)

Every year, third-year engineering students in the Marine Engineering, Naval Architecture and Offshore Engineering (MNO) degree programmes (merged into the Naval Architecture and Marine Engineering (NAME) degree programme from academic year 2022 onwards) from the Singapore Institute of Technology (SIT) showcase their work done during their Integrated Work Study Programme (IWSP) at the Marine Programmes IWSP Poster Day.

Students are required to identify an IWSP work-related engineering problem and develop a proof-of-concept (PoC) for their proposed solutions. The PoC and a poster are presented and assessed on IWSP Poster Day, and awards are given to deserving students.

“This learning activity stimulates students' problem-solving ability by applying the knowledge and skills learned in the classroom. The IWSP Poster Day also serves as a platform to deepen our partnerships with the industry. We hosted about 450 visitors, including students, academic staff, and IWSP company representatives,” said Associate Professor Wang Xin, Programme Leader, NAME.

We speak to the three Best Project Gold winners:

A Window to Lower Emissions

Myo Myat Thandar presenting her poster and project simulation at the Marine Programmes IWSP Poster Day 2022. (SIT photo: Thomas Lim)

Myo Myat Thandar, from the Naval Architecture specialisation, focused on something most would overlook: windows. She fondly remembers that as a child, whenever she felt seasick on her family trips on the ferry to Batam, Indonesia, her mother would encourage her to look out of the window. The sea breeze and view always made her feel better, imbuing her with an appreciation for windows.

On maritime vessels, windows facilitate heat transfer through solar radiation. This increases carbon emissions as more energy is required to ensure that the onboard climate is optimal for operation. A retrofitted window design could reduce heat transmission, enable downsizing to less heavy heating, ventilation and air conditioning (HVAC) units, ultimately cutting costs and energy consumption.

“We’re trained to always focus on the big picture, but sometimes, it’s the smallest things that make the biggest difference,” she said of her IWSP experience at Penguin International.

She studied the typical route of a vessel travelling from Singapore to Batam and noted the period of greatest heat transmission. After careful calculation, she created a spectrally selective window film which obstructs specific infrared rays from sunlight. The film could potentially block over 90 per cent of heat-generating ultraviolet and infrared radiation, while permitting about 70 per cent of visible light to enter, reducing heat transfer by 35 per cent.

This film is resilient to marine conditions, making it easy to maintain and could result in lower consumer costs due to decreased fuel usage. It has taught her to appreciate the simplicity of a matter. There is always room for growth, and by focusing on improving a simple problem, it could result in tangible benefits. “Even the tiniest idea could culminate in something big if we keep faith in our journey,” she said.

Propelling Safety and Efficiency

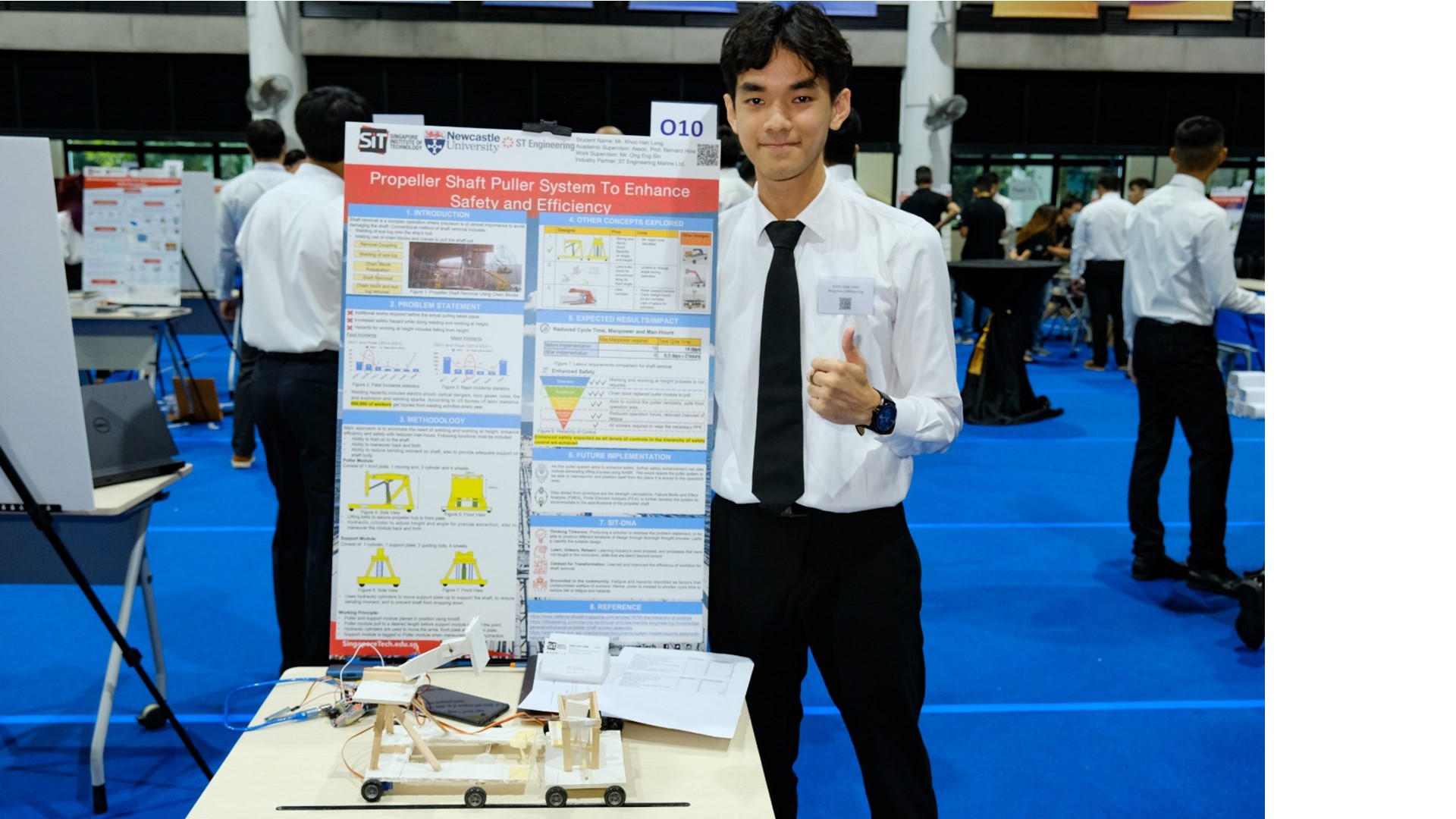

Khoo Han Long presenting his poster and project model at the Marine Programmes IWSP Poster Day 2022. (SIT photo: Thomas Lim)

According to the US Bureau of Labour Statistics, around 560,000 workers suffer welding-related injuries in the United States every year[1] from welding hazards ranging from electric shock to fire and falling at height.

Khoo Han Long, from the Offshore Engineering specialisation, wanted to propose a safer and more efficient solution for propellor shaft removal on ships, a complicated and potentially dangerous process that involves welding as well as using chain blocks and cranes to remove the shaft.

He approached his colleagues at his IWSP company, ST Engineering Marine Limited, for help. “The main approach is to eliminate the need for welding and working at height, as well as reduce man hours,” he said.

After considering alternative designs, Han Long settled on a product with two main components – a puller module and a support module. This mechanism can be put in place with a forklift and reduces the manpower needed to perform welding and other work at height. This ultimately cuts the time required for shaft removal.

To further improve it, forklifts could be eliminated altogether, relying instead on the puller system manoeuvre.

“One lesson I have learnt is to not be afraid to ask for help,” he said. “It is very important to be able to improve on technical knowledge that is not taught in the curriculum.”

Making (Gang)Way for Innovation

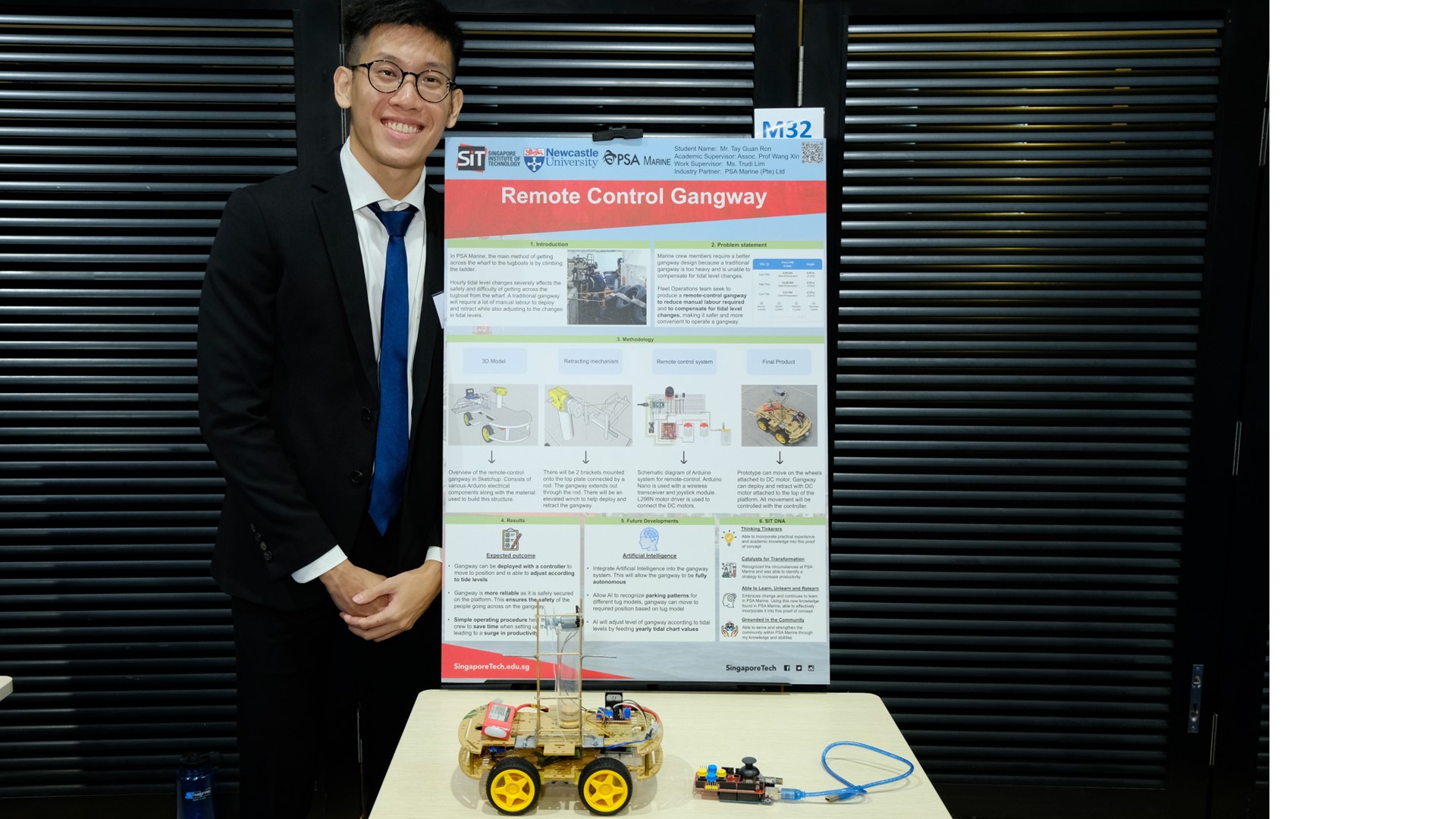

Tay Guan Ron presenting his poster and project model at the Marine Programmes IWSP Poster Day 2022. (SIT photo: Thomas Lim)

Tay Guan Ron, from the Marine Engineering specialisation, was inspired to create a remote-control gangway for his IWSP company, PSA Marine, as this has been one of the issues that the company has been trying to solve.

For the marine crew at PSA Marine, they usually had to cross the wharf to reach the tugboats by climbing a ladder. However, hourly tidal changes can make this an arduous and dangerous process. Deploying a traditional gangway requires a lot of manual labour; it is also too heavy and unable to compensate for tidal level changes.

To combat this, Guan Ron designed a remote-control gangway to compensate for tidal level changes and reduce manpower required, making it safer and more convenient to deploy.

He started by 3D-modelling the gangway and a retracting mechanism, then created a remote-control system and a wheeled prototype that can be operated and adjusted to tide levels. The simple operating procedure helps the marine crew save time when setting up the gangway. As the gangway is safely secured on the platform, it makes it safer for people to cross.

Going forward, artificial intelligence could potentially be integrated into the gangway’s system, making it fully autonomous.

“The main challenge was the time constraint, as I had to focus on assignments in the company and find time for this project,” said Guan Ron. “I learned how to manage my time efficiently and the importance of it. I believe this will help me get through obstacles in the future.”

[1] How Common Are Welding Accidents & Injuries? (2023 Statistics). https://waterwelders.com/welding-accidents-statistics/

![[FA] SIT One SITizen Alumni Initiative_Web banner_1244px x 688px.jpg](/sites/default/files/2024-12/%5BFA%5D%20%20SIT%20One%20SITizen%20Alumni%20Initiative_Web%20banner_1244px%20x%20688px.jpg)