SIT’s Machine Learning and AI Data Analytics for the Semiconductor Industry course is helping professionals like Cecilia Lim drive innovation in the manufacturing process.

SIT’s Machine Learning and AI Data Analytics for the Semiconductor Industry course Graduation Ceremony for the inaugural batch of Applied Materials learners in 2025. (Photo: SIT)

When Ms Cecilia Lim used AI-powered tools in her engineering role, she could operate them effectively but felt like she was only seeing half the picture.

“I often found myself wanting to understand how the tools worked, what algorithms powered them, how models were trained, and how to interpret their output more critically,” said the 32-year-old Process Support Engineer at Applied Materials (Applied), which makes the equipment used to manufacture computer chips.

In 2024, she enrolled in SIT’s Machine Learning and AI Data Analytics for the Semiconductor Industry course through her employer to become more adept at using AI to predict production yields and assess anomalies.

Real Problems, Real Solutions

With the dramatic rise in the number of connected devices in semiconductor manufacturing, engineers are expected not only to operate AI-driven systems and understand and improve them. SIT’s course was launched in 2024 to meet this critical need, targeting semiconductor professionals such as engineers, process managers, and equipment designers.

Spanning 13 sessions over 11 weeks, the course blends fundamental data science concepts with hands-on application using Python – all contextualised within the semiconductor industry. Learners tackle actual problems their companies face, using real production data and presenting solutions to management.

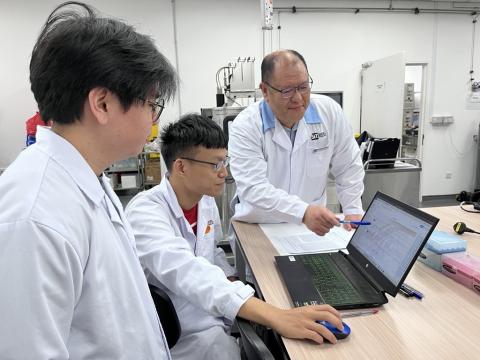

Applied Materials engineers from the Machine Learning and AI Data Analytics for the Semiconductor Industry course with A/Prof Zhou Junhong (second from right, first row) from SIT. (Photo: SIT)

“The course was thoughtfully designed. It offered a flexible pace, modular content, and practical assignments that aligned well with real-world applications. It gave me the confidence to contribute more proactively to data-driven projects. I now approach problems with a more structured, analytical mindset,” said Ms Lim, who completed eight hours of coursework a week on top of her full-time job.

In the semiconductor industry, where precision, speed, and complexity converge, skilled talent like Ms Lim is increasingly in demand. With the sector projected to reach US$1 trillion in sales by 2030[1], pressure is mounting to produce next-generation, energy-efficient chips that power technologies like electric vehicles, AI, and clean energy systems. However, a gap in talent adept in skills like AI and data analytics poses a significant challenge to sustaining this momentum.

“To stay ahead, we need to adopt new technologies faster than our competitors, and that requires engineers who are not only technically competent, but also digitally savvy,” said Mr Tan Way Tat, Ms Lim’s supervisor at Applied Materials. “While we can hire externally, developing our existing talent ensures quicker integration, stronger engagement, and long-term continuity.”

Ready to Drive Change

Ms Lim, who has a Bachelor’s degree in Materials Engineering, said SIT’s course gave her a solid grounding in methods such as regression models and decision trees. This helped her use data to make the manufacturing process, from process optimisation to defect classification and yield prediction, more efficient.

Since completing the course in July 2024, she has been involved in predictive modelling and data visualisation projects at Applied. She also helped drive digital transformation through its AIx initiative that uses AI to accelerate manufacturing insights and decision-making.

“Cecilia now contributes beyond her original role — she brings a data-driven lens to problem solving and confidently applies machine learning models to real-world challenges,” observed Mr Tan.

Ms Lim’s success story is not unique: she is one of 40 Applied Materials engineers who have benefited from SIT’s course, which has spawned 11 innovative projects across five business units in the company so far.

Encouraged by the tangible outcomes, Applied has enrolled a third cohort of 23 engineers for training, while chipmaker STMicroelectronics has also partnered with SIT to train 18 members of its quality control department.

“Upskilling is not just important, it’s essential,” said Mr Tan. “Our engineers already possess deep process knowledge, and when combined with AI and machine learning capabilities, they become powerful drivers of innovation.”

This article first appeared on The Singapore Engineer.

[1] https://www.forbes.com/sites/martineparis/2024/07/26/ai-to-drive-1-trillion-in-global-chip-sales-by-2030-as-nvidia-leads/

![[FA] SIT One SITizen Alumni Initiative_Web banner_1244px x 688px.jpg](/foodplant/openhouse/centre-professional-communication/directory/centre-professional-communication/sites/default/files/2024-12/%5BFA%5D%20%20SIT%20One%20SITizen%20Alumni%20Initiative_Web%20banner_1244px%20x%20688px.jpg)