The Energy Efficiency Technology Centre (EETC) upskilled 200 professionals and conducted 120 audits to help Small and Medium-sized Enterprises (SMEs) optimise their energy usage in its first phase of operation.

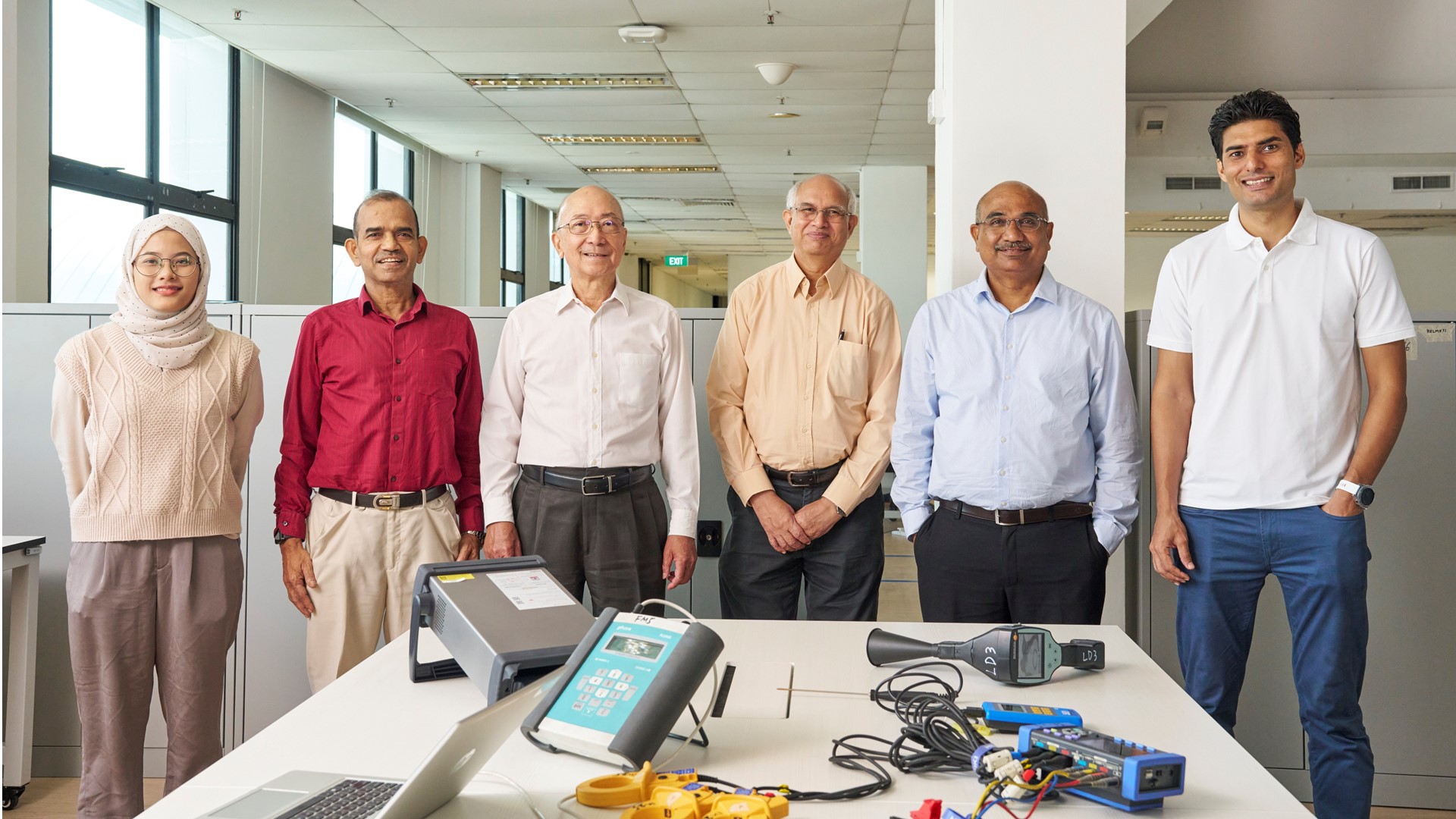

The team at Energy Efficiency Technology Centre (EETC) aims to promote and develop energy efficiency capability and the adoption of new technologies in the local energy ecosystem for industrial sectors. (SIT Photo: Keng Photography/Tan Eng Keng)

After working for about a decade in various sustainability roles, Ms Kia Jiehui joined her family business - Ichi Seiki, an engineering solutions provider. She was eager to introduce changes to help make the company greener and more energy efficient.

In 2021, she turned to the Energy Efficiency Technology Centre (EETC) at the Singapore Institute of Technology (SIT). EETC sent a team, comprising an energy specialist and SITizens doing their Integrated Work Study Programme (IWSP), to perform a comprehensive energy assessment of Ichi Seiki’s premises, and provide recommendations on reducing its energy usage.

The EETC team identified two major energy-consuming areas at Ichi Seiki which allowed Ichi Seiki to realise about 30 per cent reduction in electricity consumption for its facility. This resulted in cost savings equivalent to around $6,000 a year. Ichi Seiki was one of the many small and medium-sized enterprises (SMEs) which has since realised tangible energy savings from their collaboration with EETC.

Powering Change for SMEs

EETC was launched in 2019, in collaboration with NEA. The Centre has since been helping companies implement energy efficiency improvement measures and buildingup local industrial energy efficiency capabilities. The Centre also trains a pipeline of SIT engineering undergraduates and upskills existing practitioners in industrial energy efficiency.

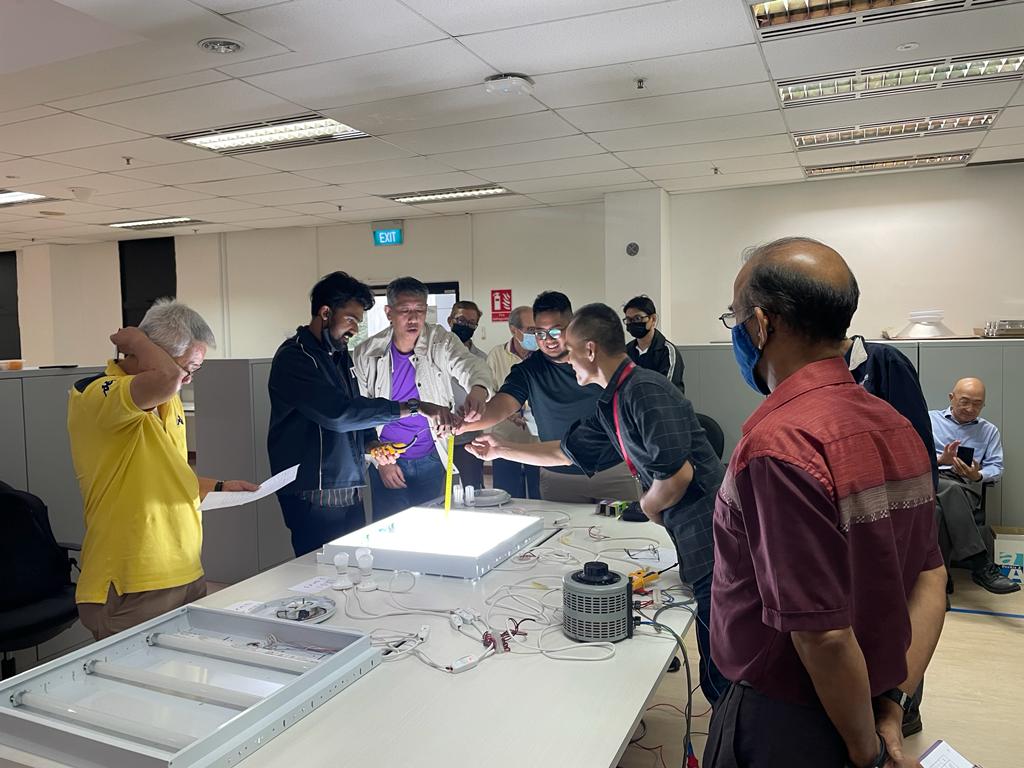

EETC conducts the Energy Efficiency and Process Optimisation for Process Industries course for industry professionals. (Photo: EETC)

Despite restrictions during the COVID-19 pandemic, the EETC team managed to audit more than 120 industrial systems for 25 SMEs and offered recommendations for optimising energy usage. Upon implementation of the suggested solutions, they could potentially save $1.6 million in electricity bills and help reduce business operation costs. These lower expenses would come from estimated energy savings of 12 million kWh. In addition, these 25 SMEs could collectively achieve an annual carbon abatement of 4.5 million kg carbon dioxide equivalent (CO2e).

Save Energy, Increase Efficiency

Professor Lock Kai Sang (standing), Head of EETC, at a meeting with his team. (SIT Photo: Keng Photography/Tan Eng Keng)

“Through the testimonials of SMEs, we are happy to hear that they have benefitted from the initiatives rolled out in Phase 1. We will build upon the momentum in Phase 1 and ramp up our efforts to conduct energy assessments for 250 industrial systems in Phase 2, which will run till 31 March 2028,” said Professor Lock Kai Sang, who heads EETC.

“The EETC energy assessment has helped identify savings in energy use and corresponding carbon abatement. EETC’s energy specialists recommended useful measures that can be implemented with a reasonable payback period, and they also shared how some of the energy savings can be achieved without substantial investments,” said Mr Lam Keng Yew, Managing Director, Onn Wah Precision Machining Pte Ltd.

Another SME that has benefited from the energy audit was PLC Industries Pte Ltd. “Being an SME, we lack the manpower and capabilities to map out our energy profile to identify areas where we can have cost savings. The EETC team was efficient and professional in collecting the data and provided a comprehensive report, which allowed us to understand our current energy profile. They also calculated the return on investment of various solutions, enabling us to make an informed decision on the solutions to adopt and implement,” recounted Ms Dione Tan, Business Development Manager, PLC Industries Pte Ltd.

Upskilling Talent

Participants at the Lighting Systems Energy Efficient Design: Audit and Analysis course, one of the Energy Efficiency Upskilling Programmes (EEUP) provided by EETC. (Photo credit: EETC)

Another key focus of the EETC is building up the competency of existing Energy Efficiency (EE) professionals while equipping new talent with requisite skills in EE. Phase 1 fully met these targets by providing specialised training for 200 EE managers, facility managers, engineers and professionals through eight Energy Efficiency Upskilling Programmes (EEUP) courses, while providing internships ranging from four months to one year at EETC for 70 students.

“By roping in industry experts as EEUP trainers, we were able to work with the industry to provide real-life case studies and relevant site visits for the participants,” shared Prof Lock.

Powering Ahead

Having gleaned significant experience in conducting comprehensive energy audits for SMEs and understanding their needs, EETC has now progressed to conducting energy assessments, as well as strengthening its outreach programmes to promote the adoption of new technologies in industrial sectors. Plans for the second phase include setting up a test-bedding lab in EETC’s upcoming SIT campus at Punggol and developing new EEUP courses.

"With a solid head start, EETC is now in a better position to understand the needs of the companies,” said Prof Lock. “Our systems and processes can be aligned efficiently for the objectives of Phase 2, which are to provide further energy savings, catalyse applied research and advance sustainability for Singapore’s industries.”

SMEs can reach the EETC team at eetc@singaporetech.edu.sg to benefit from energy assessment, Energy Efficiency Funding applications, and upskilling programmes.

![[FA] SIT One SITizen Alumni Initiative_Web banner_1244px x 688px.jpg](/openhouse2025/sit-teaching-and-learning-academy/openhouse/openhouse/directory/centre-professional-communication/sites/default/files/2024-12/%5BFA%5D%20%20SIT%20One%20SITizen%20Alumni%20Initiative_Web%20banner_1244px%20x%20688px.jpg)