For many Singaporeans, the Nicoll Highway collapse in 2004 was a shocking headline. For A/Prof Ho Jiahui, then a young student preparing for university, it was a defining moment in her path as a young engineer.

“I remember watching not just the wreckage, but the families who had lost loved ones,” she recalled. “It struck me that mistakes in our field are never just technical oversights. They carry heavy human consequences.”

Beyond technical lessons, the tragedy also impressed upon her the weight of social responsibility. As engineers, errors can ripple out to affect entire families and communities, making competence and accountability non-negotiable.

As an engineering undergrad, this awareness sharpened into technical rigour. She learned that soil behaviour is complex and that disasters can happen when designs are applied without fully understanding these limitations. One professor in particular, who taught her foundation engineering, left a lasting impression. He had the ability to make even the most technical topics come alive with stories. That combination of rigour and narrative drew her into the world of geotechnical engineering.

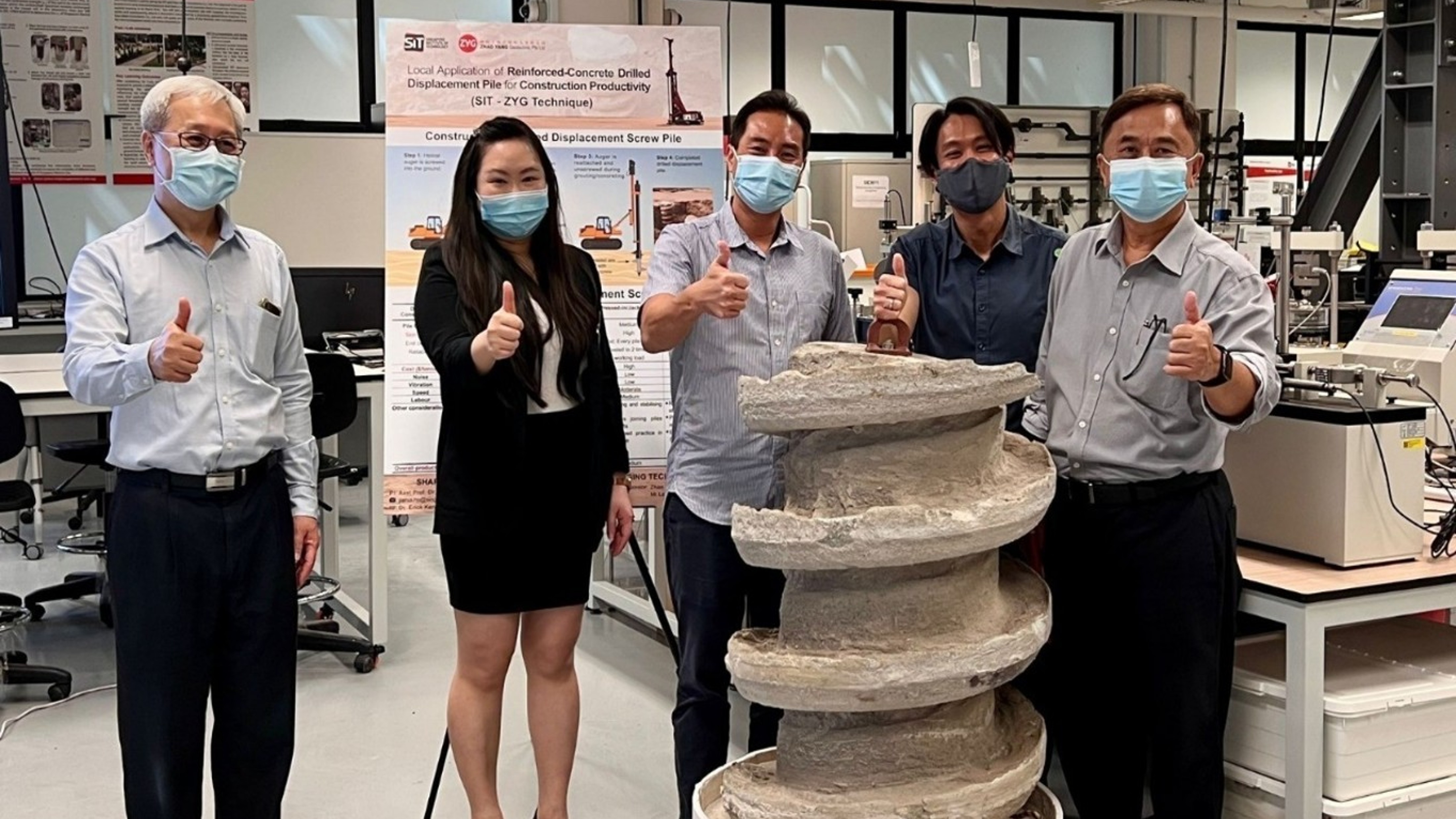

Years later, her curiosity led her to Drilled Displacement (DD) screw piles. While this was a proven method overseas, it had yet to be tested in Singapore’s soils. Recognising its potential as a greener and more efficient approach, she spearheaded efforts to adapt it locally, culminating in the first BCA approval for use at a site here.

Rethinking Foundations

What exactly is a DD screw pile? A/Prof Ho explains it simply, “Imagine a giant metal screw, what we in the industry call the ‘auger’, pushes soil aside as it drills in, instead of digging it out. As the auger withdraws, concrete is pumped in, leaving behind a reinforced screw of concrete locked into the ground with almost no waste.”

The benefits are striking. While a conventional bored pile may take more than a day to install, a DD screw pile can be completed in under two hours. They use about a third less concrete, generate no messy spoil (soil and debris generated during excavation and construction activities), and create far less noise and vibration than driven piles.

“Faster, cleaner, and less disruptive,” she said. “That means shorter project timelines, lower costs, and less impact on nearby communities.”

Trials Beneath Our Sands

The first trials were conducted on reclaimed sand, with piles fitted with sensors and results compared against over 1,000 advanced computer simulations.

During practice runs with the contractor, the auger compacted the loose sand so much that soil strength increased. This densification increased the soil’s strength. This increased soil strength meant that the finished pile could carry higher loads when installed. Productivity also improved dramatically, from four hours per pile at the start to about one hour as the construction team gained experience.

Building Green, Building Smart

The innovation couldn’t have arrived at a better time. With Singapore working towards net-zero emissions by 2050, DD screw piles reduce carbon by using less concrete. With no spoil to dispose of, they also cut truck movements, ease road congestion, and lessen pressure on Semakau Landfill.

They address manpower challenges too. Faster installation means fewer workers on site, helping contractors adapt to tighter foreign worker quotas.

“In many ways, they align perfectly with Singapore’s Green Plan 2030 and broader regulatory shifts in the construction sector,” A/Prof Ho noted.

Conditions Ahead

However, take-up has been cautious with a mix of cost concerns and unfamiliarity with new technology. Contractors face upfront investment in specialised rigs, and many would rather stick to tried-and-tested methods. Misconceptions compound the issue; some worry the screw shape is hard to fabricate accurately or that flanges might break off under stress. But research shows otherwise, where variations often increase capacity, with the piles being robust when installed correctly.

“The real gap is design guidance tailored to Singapore’s soils,” she added. “That’s what we’re working on next.”

Looking ahead, A/Prof Ho is focused on three priorities: establishing design rules tailored to Singapore’s soils, exploring low-carbon materials that can push emissions even lower, and reusing piles left underground at demolition sites.

Beyond materials and methods, she also points to automation. Installation rigs already capture torque and force data. With data and analytics, machines could auto-adjust in real time, optimising pile performance while reducing reliance on human judgement.

A Lesson in Responsibility

For her students, she offers a reminder, “Never lose sight of the human side of engineering. What we design affects lives.” Alongside this, she encourages them to master soil mechanics, stay curious about global innovations, and embrace digitalisation. In her view, the future belongs to engineers who can meld technical expertise and digital savviness, while never losing sight of the human impact they could bring.

For A/Prof Ho, the most fulfilling part is seeing research move from idea to industry, with students involved every step.

“When we first introduced DD screw piles, there was scepticism. But trials proved they work, and they’re better for productivity and sustainability,” she reflected.

“In many ways, this is just the start,” she added. “We are learning how to make the method not just practical, but transformative in the right contexts. It is the combination of industry trust and technical breakthroughs that will decide how far we can take DD screw piles in laying the new foundations of Singapore’s built environment.”

![[FA] SIT One SITizen Alumni Initiative_Web banner_1244px x 688px.jpg](/openhouse2025/sit-teaching-and-learning-academy/centre-professional-communication/centre-professional-communication/sit-teaching-and-learning-academy/directory/centre-professional-communication/directory/sites/default/files/2024-12/%5BFA%5D%20%20SIT%20One%20SITizen%20Alumni%20Initiative_Web%20banner_1244px%20x%20688px.jpg)