About Course

Electric motor driven systems (MDS) account for over 50% electricity consumption. MDS can be inefficient and costly to operate if they are not properly designed, selected, and maintained.

Facility and operation managers can avoid unnecessary energy wastage by selecting MDS that are well suited to their applications and making sure that they are well maintained.

Cost-effective design, operation, and maintenance of a MDS requires attention not just to individual piece of equipment but to the total system performance which necessitates an analysis of the interaction of both the supply and demand sides.

At the end of this course, participants will be able to:

- Gain in-depth knowledge and skills to identify and evaluate energy conservation opportunities involving motor-driven equipment

- Implement facility energy management programme involving motor-driven equipment

- Familiarise with current and emerging energy-efficient motors, the associated power electronics, and control technologies

- Design energy efficient motor-driven systems through theory-based calculations, and the appropriate sizing and selection of energy efficient components, such as fans and pumps

- Evaluate system performance of MDS taking account of interactions of both supply and demand sides, and be able to deploy cost-effective measures to improve energy performance

- Conduct performance evaluation and energy audit of motor-driven systems through authentic learning with hands-on practical sessions

Who Should Attend

Prerequisites

Bachelor degree in engineering or engineering diploma with 2 years of relevant working experience

Learning Outcomes

DC motors

- System configurations

- Structure of DC machines

- Principle of DC machines

- Converters for DC motor drives

- DC motor control

- Application examples of DC drives

Induction motors

- Design and construction of induction motors

- Theory and fundamental principles

- Classification of motors

- Torque speed characteristics

- Starting requirements

- Soft starter

- Conventional speed control

- Transient and dynamics

- Power supply & cabling requirements

- Case studies of motor starting problems

Permanent magnet brushless motor drives

- PM brushless machines

- Brushless electronically commutated (EC) motors

- System configuration

- Inverters for PM brushless motors

- PM brushless motor control

- Application examples

Application considerations

- Motor ratings & specifications

- Motor load and mechanical considerations

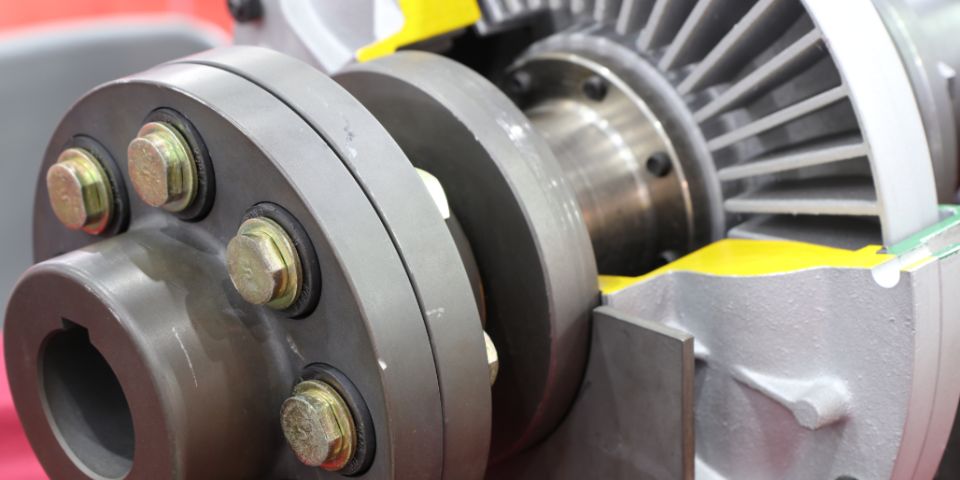

- Transmission drives

- Electrical calculations

- Mechanical calculations

- Matching motor/drive’s ratings to load requirements

- Power supply considerations

- AC drives cabling

- Protection of motor and drive

- Preventive and predictive maintenance

- Application examples

Power electronics for motor control

- Power semiconductor devices

- Thyristor characteristics and applications

- Insulated-gate bipolar transistors

- AC to DC conversion

- DC to AC conversion

- DC to DC conversion

- PWM principles

AC motor drives

- System configurations

- Operation of variable speed ac drives (VFDs)

- Modern features of VFDs

- VVVF principles

- Field weakening control

- Acceleration and deceleration

- Regenerative braking

- Open-loop and closed-loop control

- Direct torque control

- Motors suitable for inverter operation

- Common application problems of VSDs and solutions

- Transformer, converter/inverter and motor interaction

- Rating specifications

- Cabling requirements

- Application examples

Supply harmonics

- Supply harmonics due to drives

- Adverse effects of harmonics

- Harmonic distortions

- Harmonic resonance problems

- Problem with power capacitors

- Solving harmonic problems

- Phase shift transformers

- Harmonic filters

- Compliance with standards and requirements of certifying bodies

- Case studies of harmonic problems

Reducing power factor cost

- Power factor explained

- Cause of low power factor

- Benefits of power factor improvement

- Methods for power factor improvement

- Avoiding harmonic resonances when installing capacitors

- Economics of power factor

Motor efficiency

- Motor efficiency standards and requirements

- Energy losses in motors

- Impact of motor loading on efficiency

- Advanced motor technologies

- Design and performance of energy efficient motors

- Evaluating motor energy efficiency opportunities

- Premium efficiency motor application considerations

- Economics of energy efficient motors

Variable speed drives for energy efficient applications of fan, pump and compressor systems

- Fan and system characteristics

- Pump and system characteristics

- Affinity laws

- Variable speed drive for energy efficient flow control

- Case studies on fan system improvement

- Case studies on pump system improvement

- Case studies on compressed air system improvement

Energy management for motor-driven systems

- Establishing a motor management program

- Assessing motor and drive system operating conditions

- Selecting the right motor

- Conducting energy audit for MDS

- Application of VFD for pumps, fans, compressors

- Addressing electrical distribution and power quality issues

- Sustaining efficiency with proactive maintenance planning

Energy audit of motor-driven systems

- Planning and organising the audit for motor-driven systems

- Initial data collection and evaluation

- Obtaining list of significant motors and driven systems with relevant data

- Understanding the electricity charges

- Measuring and monitoring the power quality of the plant electrical distribution system

- Taking field measurements of the motor-driven systems

Teaching Team

Er. Dr. LOCK Kai Sang

Professor, Engineering, Singapore Institute of Technology

Nadarajan Sivakumar

Associate Professor, Engineering, Singapore Institute of Technology

Cao Shuyu

Lead Professional Officer, Singapore Institute of Technology

Course Details

| Schedule | Topic |

|---|---|

| Day 1 |

|

| Day 2 |

|

| Day 3 |

|

| Day 4 |

|

| Day 5 |

|

Certificate and Assessment

A Certificate of Attainment will be issued to participants who:

- Attend at least 75% of the course

- Undertake and pass non-credit bearing assessment during the course

Participants who meet the attendance requirement but do not pass the assessment will receive a Certificate of Participation.

Fee Structure

The full fee for this course is S$5,450.00.

| Funding Category | Eligible Funding | Course Fees Payable After Funding |

|---|---|---|

| Singapore Citizen (Below 40) | 70% | S$1,635.00 |

| Singapore Citizen (Above 40) Funded under SkillsFuture Mid-Career Enhanced Subsidy (MCES) | 90% | S$635.00 |

| Singapore PR / LTVP+ Holder | 70% | S$1,635.00 |

| Non-Singapore Citizen | Not Eligible | S$5,450.00 |

Note:

- All fees above include GST. GST applies to individuals and Singapore-registered companies.

Course Runs

New Engineering Micro-credentials Launching Soon!

Exciting news! We are introducing new micro-credentials in Electrical and Electronic Engineering & Infrastructure and Systems Engineering. Be among the first to know by registering your interest today! Register now →