A one-stop centre for innovation at the Singapore Institute of Technology is offering services to drive innovation in the industry, from ideation to co-development of new or improved solutions as well as test-bedding.

InnoHub, helmed by SIT’s A/Prof Ivan Lee (back row, sixth from left), comprises four innovation centres. (SIT Photo: Keng Photography/Tan Eng Keng)

Innovation can be achieved with major breakthroughs or more often through improvements that can lead to the introduction of new products, processes, designs, business models or services – and a university in Singapore is taking comprehensive steps to play an integral role in catalysing innovation in the industry.

The Singapore Institute of Technology (SIT) set up the Innovation Hub, also known as InnoHub, early this year to provide an integrated end-to-end innovation infrastructure that helps businesses drive innovation, from ideation to product development and sample production for market testing, prior to scaling up.

“The idea is to provide integrated solutions to multidisciplinary problems and journey with the industry in their innovation pursuits,” says Associate Professor Ivan Lee, SIT’s Vice President for Innovation, who helms InnoHub as its head.

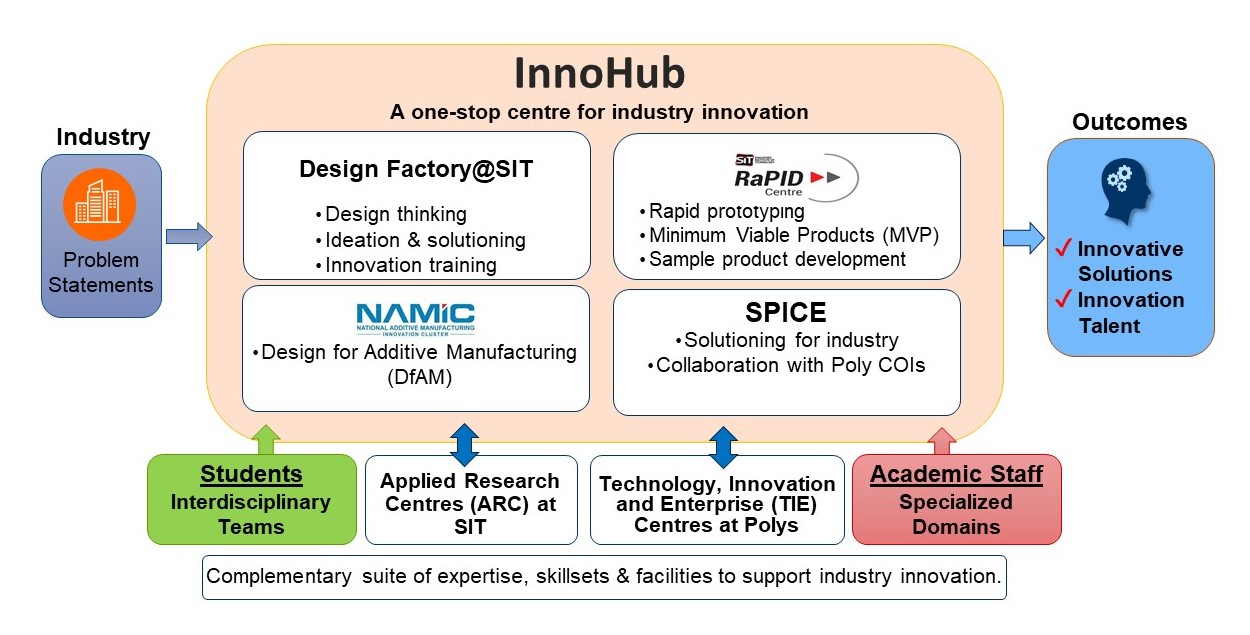

Encompassing four innovation-focused centres, the InnoHub aims to be a one-stop centre for industry innovation. The innovation centres include the Design Factory@SIT (DF@SIT), the Rapid Product Innovation and Development (RaPID) Centre, the SIT-Poly Innovation Centre of Excellence (SPICE), and the National Additive Manufacturing Innovation Cluster (NAMIC) Hub@SIT.

InnoHub – An integrated innovation infrastructure to support industry innovation.

Driving Innovation in an Open Ecosystem

As a one-stop centre, InnoHub drives innovation by ideating and co-developing innovative and commercially viable solutions with industry, pooling together domain experts who possess deep industry know-how as well as facilities and capabilities across different disciplines to provide an integrated innovation infrastructure.

This is exemplified by the Design Factory@SIT (DF@SIT) which supports businesses in improving their values through human-centric designs that solve real-world problems. Through design innovation and experimentation, DF@SIT co-creates unique value propositions with companies to improve their business models, products, processes, designs and/or services.

Meanwhile, the Rapid Product Innovation and Development (RaPID) Centre offers speedy and flexible prototyping and sample product development capabilities. For example, it recently collaborated with a local company to develop a solution to deter birds from picking food scraps off dustbins. The RaPID centre provided core capabilities in engineering design, systems integration and iterative development to enhance the realisation of the idea. Further refinements to the prototype were made until it was proven workable for scaling up.

Likewise, the National Additive Manufacturing Innovation Cluster (NAMIC) Hub@SIT will co-develops advanced additive manufacturing (such as 3D printing) technologies for industry test-bedding and adoption. NAMIC offers a range of services including AI-driven generative designs, structural topology optimisation and pilot production to enable the industry to innovate with speed and efficiency.

The SIT-Poly Innovation Centre of Excellence (SPICE) provides small and medium-sized enterprises (SMEs) with access to expertise, facilities and equipment, and a diverse talent pool within SIT and across the various Centres of Innovation at the Polytechnics to help them develop new products and services. Tapping on SIT’s and the Polytechnics’ existing resources reduces the risks associated with early-stage investments, and allows them to focus on creating the right products for the right problems.

Companies can engage the innovation centres as required. A recent example saw both DF@SIT and RaPID Centre collaborating with a logistics company to design and develop an improved climate-controlled storage unit. Such storage solutions have been invaluable for storing medications and food supplies amid the global supply chain disruption challenges.

Driving innovation in an open ecosystem, InnoHub also extends its network of innovation partners to include SIT’s Applied Research Centres and other external collaborators. Leveraging this, InnoHub coordinates the required resources and capabilities to undertake more extensive and multi-disciplinary projects with industry, traversing across the ecosystem’s value chain.

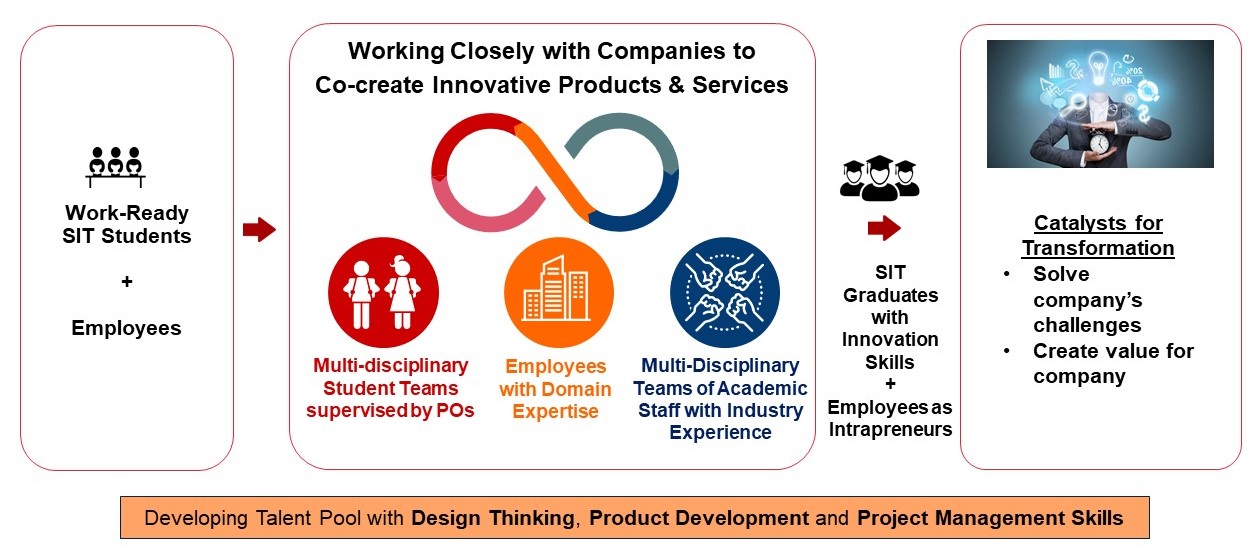

Developing Catalysts for Transformation

Beyond gaining access to academic staff and students, companies will be able to access a pool of upcoming graduates who have gained practical experience and innovation skills by working on industry projects.

These graduates form a talent pipeline of innovators and value creators for the companies. By working together with the hub and its ecosystem of partners on innovation projects, the companies’ employees will also deepen their technical skills and acquire innovation skillsets to catalyse and support business transformations.

Nurturing a talent pipeline of innovators and value creators for the industry.

InnoHub is rolling out structured innovation programmes to train employees of interested companies on practical innovation skills by working on company-specific projects. The trainees will learn the relevant product development methodology and innovation skills that will help to catalyse innovation in their companies.

“Through InnoHub, SIT will work with industry to co-develop and adopt innovative solutions facilitated by our industry-friendly intellectual property (IP) policies. We will also train the companies’ employees in technical and innovation skills to support their business transformation plans”, says A/Prof Lee.

Companies can reach out to the team at innohub@singaporetech.edu.sg to innovate or attend structured innovation programmes.

This article first appeared in GovInsider.